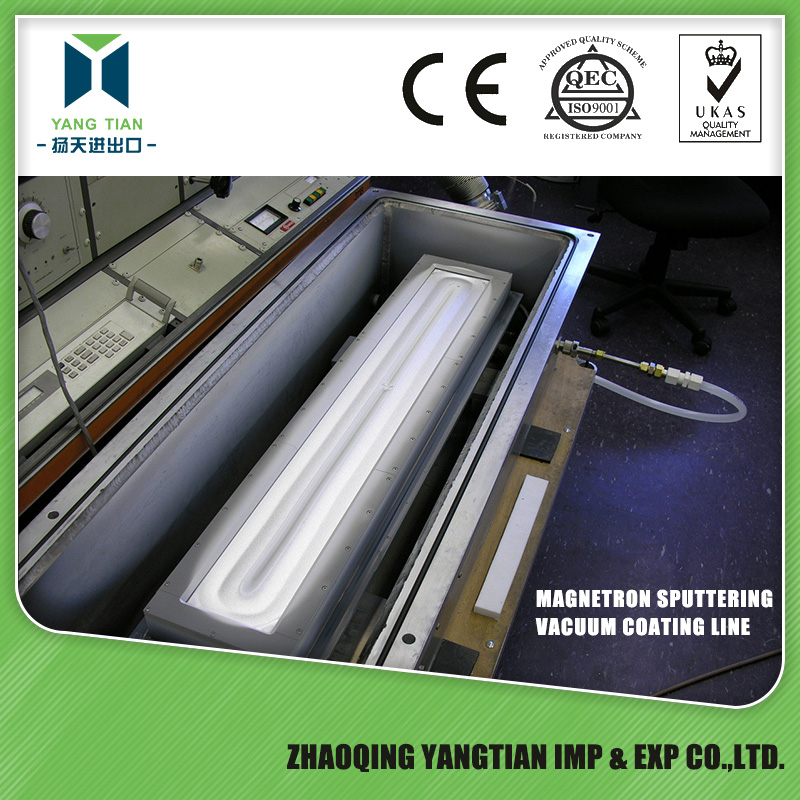

Product Display

Product Introduction

Almost all of the new sputtering equipment use strong magnets to move electrons into a spiral to accelerate the ionization of argon around the target, resulting in an increase in the probability of impact between the target and argon ions and improve the sputtering rate.

Generally, DC sputtering is used for metal coating, while RF AC sputtering is used for non-conductive ceramic materials. The basic principle is to use glow discharge (glow discharge) to hit argon (Ar) ions on the surface of target (target) in vacuum, and the cations in the plasma will accelerate to the negative electrode surface of the spattered material. This impact will make the material of the target fly out and deposit on the surface of the target.

A thin film is formed on the substrate.

Generally speaking, there are several characteristics of sputtering coating:

(1) metal, alloy or insulator can be made into thin film material.

(2) the film with the same composition can be made from multiple and complex targets under appropriate setting conditions.

(3) the mixture or compound of target material and gas molecule can be made by adding oxygen or other active gas to the discharge

atmosphere.

(4) the input current and sputtering time of the target can be controlled, and the high precision film thickness can be easily obtained.

(5) it is more advantageous to produce large area uniform film than other processes.

(6) the sputtered particles are almost not affected by gravity, and the positions of the target and the substrate can be arranged freely.

(7) the adhesion strength between the substrate and the film is more than 10 times that of the general evaporated film, and because the sputtered particles have high energy, the film will continue to diffuse on the film-forming surface to obtain a hard and dense thin film. At the same time, this high energy makes the substrate as long as the lower temperature to get the crystalline film.

(8) the nucleation density of the film is high at the initial stage of its formation, and the ultra-thin continuous film below 10nm can be produced.

(9) the target has a long life and can be produced automatically and continuously for a long time.

(10) the target can be made into various shapes, which can be better controlled and efficient with the special design of the machine.

免責聲明:當前頁為 Color Mirror Coating Sputtering Line產品信息展示頁,該頁所展示的 Color Mirror Coating Sputtering Line產品信息及價格等相關信息均有企業自行發布與提供, Color Mirror Coating Sputtering Line產品真實性、準確性、合法性由店鋪所有企業完全負責。世界工廠網對此不承擔任何保證責任,亦不涉及用戶間因交易而產生的法律關系及法律糾紛,糾紛由會員自行協商解決。

友情提醒:世界工廠網僅作為用戶尋找交易對象,就貨物和服務的交易進行協商,以及獲取各類與貿易相關的服務信息的渠道。為避免產生購買風險,建議您在購買相關產品前務必確認供應商資質及產品質量。過低的價格、夸張的描述、私人銀行賬戶等都有可能是虛假信息,請您謹慎對待,謹防欺詐,對于任何付款行為請您慎重抉擇。

投訴方式:fawu@gongchang.com是處理侵權投訴的專用郵箱,在您的合法權益受到侵害時,請將您真實身份信息及受到侵權的初步證據發送到該郵箱,我們會在5個工作日內給您答復,感謝您對世界工廠網的關注與支持!